A 900

A 900

REDLINE Band saw Band saw

When the band saw blade has finished cutting the trunk, the only operator simply pushes the strain in the cradle of the log splitter and propels the dual controls of the same, by starting the cutting of another strain.

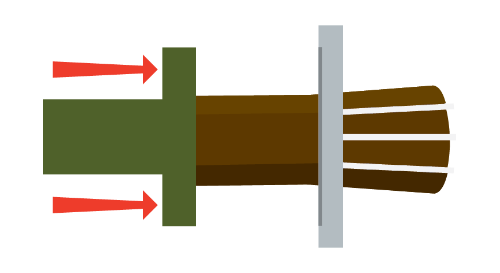

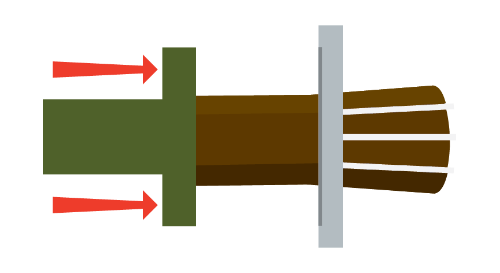

The log shall then, alone, to break the strain that has been placed in the cradle. In fact, the plate (piston-operated) pushes the strain against the blades, causing the splitting operation and then automatically return to the starting position.

The logs fall into a conveyor that will load the conveyor belt to form the pile, or load any means of transport to it approached.

The ergonomic principle on which is based the workstation allows a single operator to carry out a very high production, safely. The standard equipment includes the hydraulic adjustment of the height of the blades, a knife to 2/4 or 2/6 streets and the truck with rubber wheels (not approved).

The log of each model includes: pump, cylinder, Distributor and a large tank that ensures the cooling of the liquid. The machine is easily reducible into its overall dimensions for towing.

| TECHNICAL DATA | A 900 | ||

|---|---|---|---|

| Splitting force | ton | 16 | |

| Bandwheels | mm | 900 | |

| Maximum inlet passage | mm/in | 580 | |

| Minimum tractor power | hp/kW | 35 | |

| Combined action | PTO + ELECTRIC MOTOR 20 hp |

EXTRAS AND CONFIGURATIONS

Other extras and configurations

- CONVEYOR BELT

Conveyor belt with PVC or rubber band with loading 2.20 m or 5 m heigth (foldable for transport).

- HYDRAULICADJUSTMENT OF HEIGHT BLADE GUIDE

Hydraulic adjustment of height blade guide

- SPARE BLADES

Spare blades to 2/6 or 2/4 blades

- ROLLER FACILITATOR

Roller facilitator at the end of the work plan

- THIRD WHEEL LOADER

Third wheel loader

- HYDRAULIC DRAW BLADE

Hydraulic draw blade with hand pump.

- SHUTTLECOCKS WITHOUT CORK

Shuttlecocks without cork with lubrication system.

TECNOLOGIE

INFORMATION REQUEST

Electric motor

Electric motor Power take off tractor

Power take off tractor

900 mmBandwheels diameter

16 tonSplitting force

35 HpMinimum required tractor power

Electric motor

Electric motor Power take off tractor

Power take off tractor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US