PTH 1000/1000 E

PTH 1000/1000 E

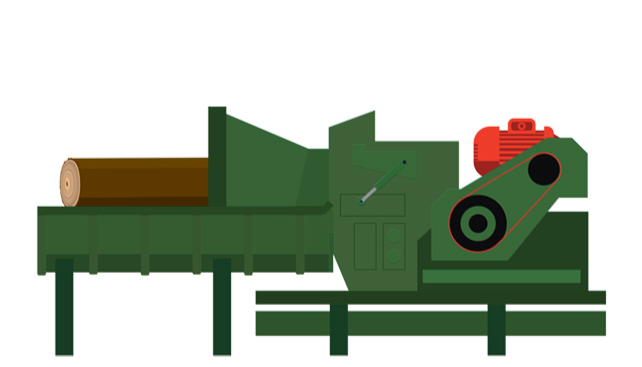

GREENLINE Chippers Electric motor

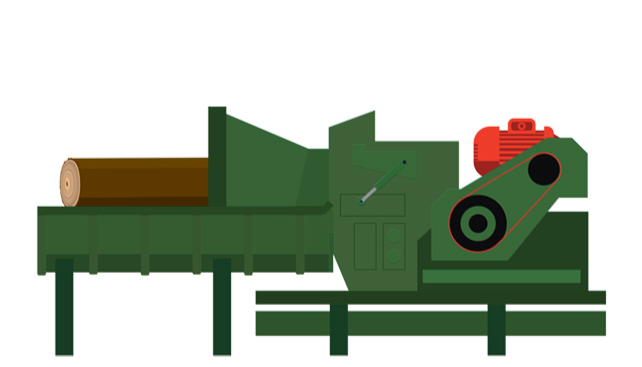

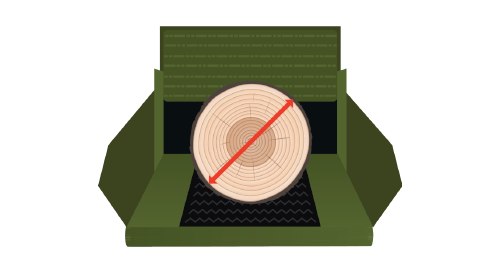

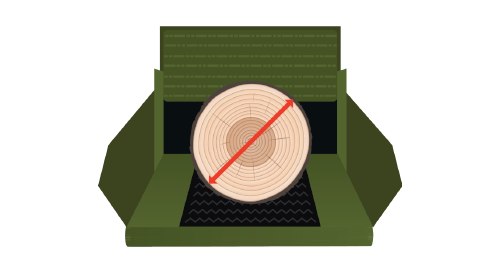

PTH 1000/1000 E is one of the medium power machines within Pezzolato drum chippers, whose drum diameter measures 1000 mm (3′ 3.37”).

Its feeding mouth is 1000 mm (3′ 3.37”) wide.

Able to produce up to 200 m3 chips per hour, it guarantees high throughput.

Mainly used in: biomass power plants, pellet-briquettes plants, saw mills and yards for chipping. It is ideal to chip saw mills waste and small diameter logs. The feeding is given by the use of rubber bands, vibrating channels and tables, chain conveyors.

The maximum chipping diameter logs is 600 mm (23.62”), for feeding without operator, maximum diameter logs: 450 mm (17.72”).

Powered by electric motor of 200 kW.

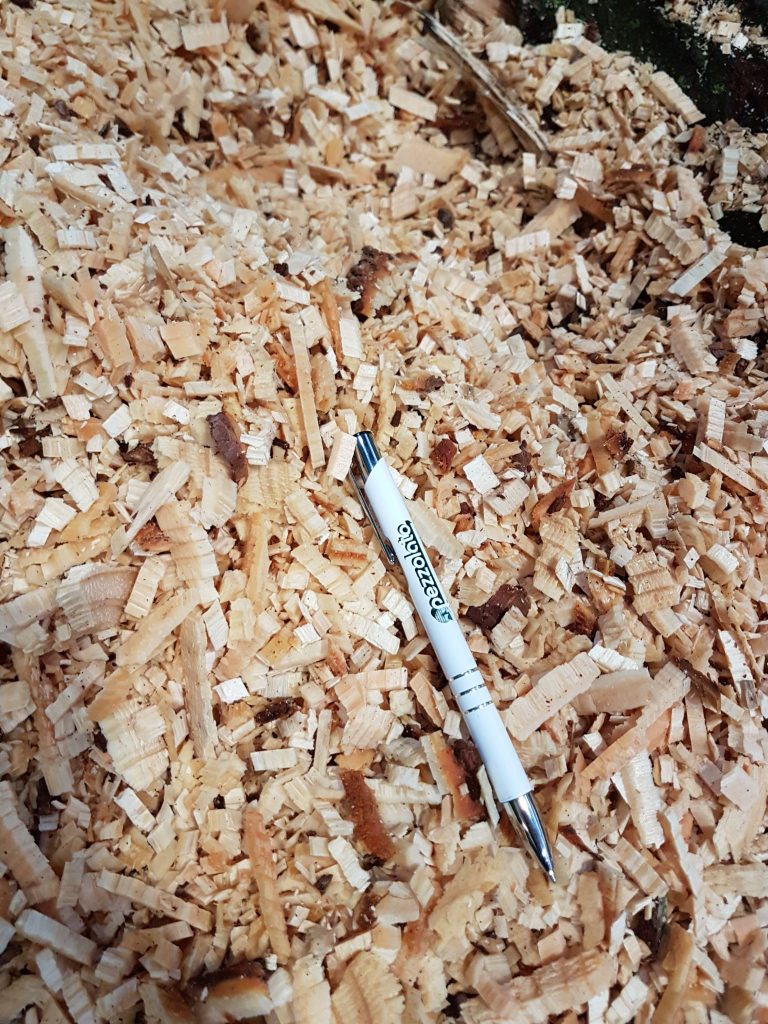

Thanks to the closed drum and the three blades, in standard configuration, they produce high quality chips, whatever wood is cut, considerably reducing fuel consumption.

The sharp cut through the blades and the drum’s inertia reduce the machine’s efforts and stress, thus confirming the well-known solidity of Pezzolato wood chippers.

The wear parts of all machines are simple to replace in short maintenance times and cheap.

The electronic controller suggests any ordinary and extraordinary maintenance operations to be performed according to the manufacturer’s maintenance plan.

Chipping dimeter and declared production are variable according to the available power, wood type and chips size.

| TECHNICAL DATA | PTH 1000/1000 E | ||

|---|---|---|---|

| Electric motor power | kw | 200 | |

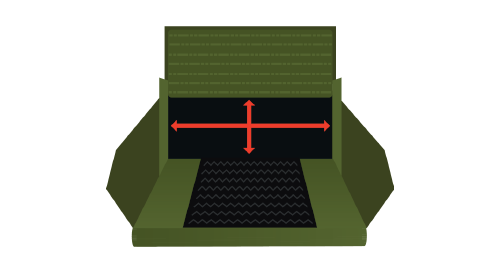

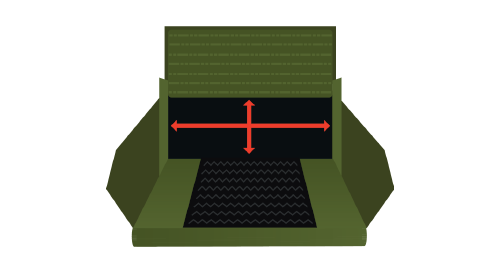

| Maximum inlet passage | mm/in | 1000 x 600 mm / 3' 3.37'' x 23.62'' | |

| Knives | n° | 4 | |

| Hourly throughoutput | m³/h | 180 ÷ 200 | |

| Drum diameter | mm/ft | 1000 mm / 3' 3.37'' | |

| Drum width | mm/ft | 1000 mm / 3' 3.37'' | |

| Upper rollers | n° | 1 | |

| Lower roller | n° | 2 |

EXTRAS AND CONFIGURATIONS

TANK FOR LOADING WOOD CHIPS

Tank for loading wood chips produced by external machinery. Chips can be loaded and integrated into the cycle, in order to be sieved

METAL DETECTOR

Metal detector to defect possible metal foreigh bodies before feeding, preventing damage to the machine

VIBRATING CONVEYOR

Vibrating conveyor to compact the material to avoid the wood clogging.

CHARGER FOR SHORT LOGS

Charger for short logs with multiple feeding chains and side walls where short logs can be loaded in bulk

LOADING STATION FOR SLABS

To stock the material to be processed in big quantities and optimise working cycles.

LOG LOADER

The best loader is provided according to the wood to be processed.

UNLOADING CHAIN CONVEYORS

Able to discharge the chips at any height or distance, to easily allow direct loading into vehicles

ROTATING CONVEYORS

These allow loading of several trucks even if they are located in different positions.

SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

LOADING TABLE WITH CLOSED CHAINS

Loading table with closed chains especially suitable for mixed material; both large and small wood pieces are smoothly delivered into the feeding conveyor, thus preventing any special waste.

SIEVE FOR CHIPS

For the refining and sifting of the chipped wood

Other extras and configurations

- HIGH EFFICIENCY ELECTRIC ENGINE

High efficiency electric engine with adequate power, it ensures low fuel consumption and less noise.

- SOUNDPROOF CABIN

Soundproof cabin protects the operator from the noise and dust.

- STATIONARY CRANE

Stationary crane for systems with operator feeding.

INFORMATION REQUEST

Electric motor

Electric motor

200 kw Electric motor power

450 mm / 17.72'' (for feeding without operator) Maximum chipping diameter

1000 x 600 mm / 3' 3.37'' x 23.62'' Maximum inlet passage

Electric motor

Electric motor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US