PTH 40.70

PTH 40.70

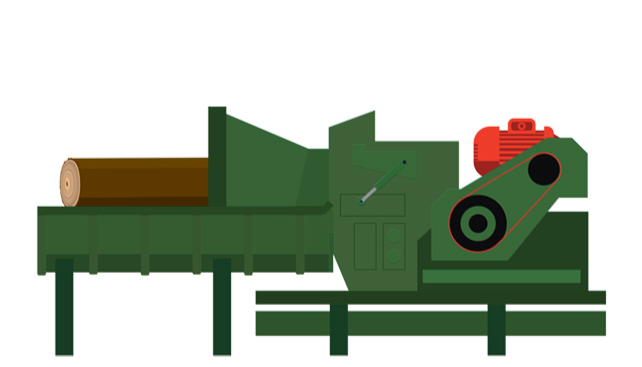

GREENLINE Chippers Electric motor

A chipper with an open or closed drum depending on the need.

The machine has the sturdy structure of Pezzolato chippers, guaranteeing reliability and excellent performance.

The width of the loading chute allows to easily feed large volumes of material, also when using mechanical means (the opening is 640 x 400mm). For manual feeding the chipper is equipped with a sturdy safety bar that keeps the operator safe during use.

A large horizontal roller with hooks, aided by a feed conveyor inside the hopper (on request a second feed conveyor can be supplied for the hopper tipper), allows material to be easily fed into the machine.

The interchangeable calibration grid allows to choose the dimensions of the chips and ensures that they are uniform and even.

The discharge fan, with interchangeable volutes, allows the wood chips to be expelled smoothly through the discharge pipe, which is equipped with an adjustable deflector at the end.

The main wearing parts are specially designed for easy replacement, as well as having a low cost.

| TECHNICAL DATA | PTH 40.70 | ||

|---|---|---|---|

| Electric motor power | kW/hp | 55-75 | |

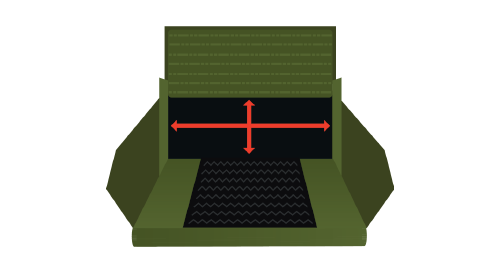

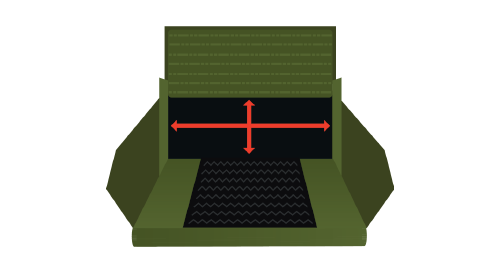

| Maximum inlet passage | mm/in | 640 x 400 mm / 25.20 x 15.75'' | |

| Knives | n° | 3/4/8 | |

| Hourly throughoutput | m³/h | 20 ÷ 25 | |

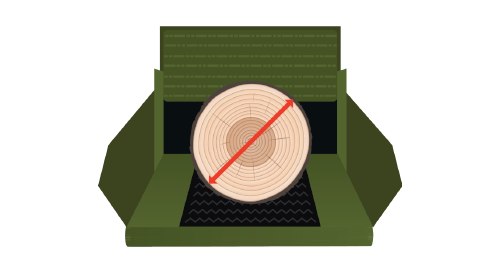

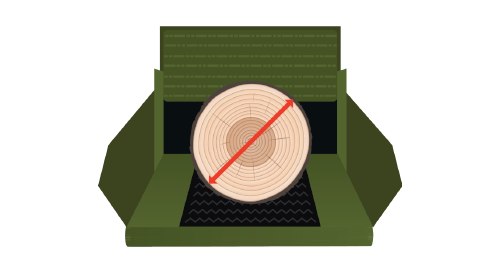

| Drum diameter | mm/in | 520 mm / 20.47'' | |

| Drum width | mm/in | 640 mm / 25.20'' | |

| Hooked steel feeding conveyor width | mm/in | 650 mm / 25.59'' | |

| Hooked steel feeding conveyor lenght | mm/in | 500 mm / 19.69'' | |

| Cutting depth adjustment | mm | 13 |

EXTRAS AND CONFIGURATIONS

SECURITY BAR

Removable security bar, for hand feeding

HOPPER WITH FEEDING CHAIN

Hopper with feeding chain, hydraulic drive, to increase the aggressiveness of the machine feeding.

Radio remote control

Radio remote control, to manage the chippers main activities at a distance

Electronic controller with 5" "touch screen" panel

Other extras and configurations

- Wear–resistant Hardox metal sheets for discharging fan

- HYDRAULIC ORIENTATION DISCHARGE TUBE

Hydraulic orientation (deflector rotation and direction) discharge tube

- RADIO REMOTE CONTROL

Radio remote control to manage the chipper’s main activities at a distance

- NO STRESS ELECTRONIC DEVICE

NO STRESS electronic device, available on all standard machines, automatically regulating the in-feed of material according to the available power

- SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

INFORMATION REQUEST

55-75 kW kW Electric motor power

reduced by 250 mm Maximum chipping diameter

640 x 400 mm / 25.20 x 15.75'' Maximum inlet passage

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US