COMPOST LINE

HOME / COMPOST LINE / HAMMER SHREDDERS / S 9000

S 9000

S 9000

Compost Line Hammer shredders

Middle-great dimension machines, studied for the disposal of the organic waste (for compost production) and of the wood scraps (for biomass production).

They can be driven by the tractor’s PTO or by an autonomous diesel or electric motor.

Their capacious hopper and their high performance confirm these machines as ideal to operate in municipal ecologic areas, for third parties and for professional compost producers.

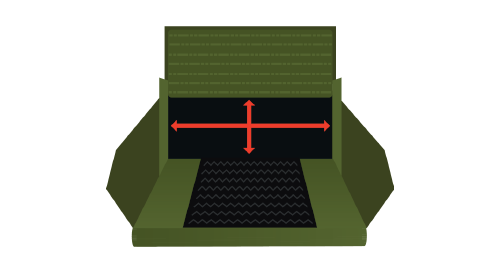

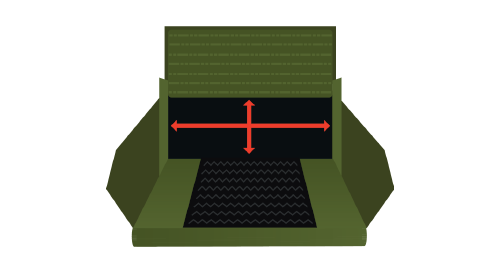

A conveyor belt with closed chains, placed at the end of the hopper, together with a toothed roller, conveys and presses the material towards the action of the hammers.

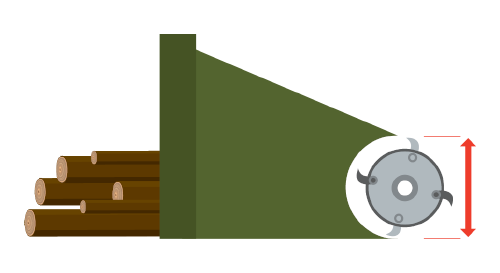

These machines have a special shredding mechanism, including a rotor, which, operating from the top down, brings the material against a fixed plate, assuring a fine and uniform fiberisation

of the material.

The rotor, composed by many discs positioned side by side, minimizes the risk of rupture in case unprocessable material is accidentally introduced in the machine.

According to the usage purposes, different types of hammers can be mounted (standard or Widia reinforced).

An electronic device adjusts the feeding of the material to be shredded, according to the available power.

A rubber discharging conveyor or a deflector for the discharge to the ground are included in the standard fitting of this version.

| TECHNICAL DATA | S 9000 | ||

|---|---|---|---|

| Minimum tractor power | hp/kW | 90 hp / 67 kW | |

| Diesel engine power | hp/kW | 205 hp / 153 kW | |

| Electric motor power | kW/hp | 90 kW / 120 hp | |

| Hopper dimensions | mm/ft | 3500 x 1800 x 800 mm / 11' 5.79'' x 5' 10.87'' x 31.50'' | |

| Width of measuring roller | mm/in | 1000 mm / 3' 3.37'' | |

| Dosing roller max opening | mm/in | 350 mm / 13.78'' | |

| Chopping chamber diameter | mm/in | 780 mm / 30.71'' | |

| Loading chain dimensions | mm | 3000 x 1000 mm / 9' 10.11'' x 3' 3.37'' | |

| Number of hammers | n° | 96 | |

| Hammers thickness | mm/in | 12 mm / 0.472'' | |

| Hammers peripheral speed | m/s | 62 | |

| Hourly throughoutput | m³/h | 30 ÷ 40 | |

| Overall dimensions | mm/ft | 7900 x 2300 x 3000 mm / 25' 11.02'' x 7' 6.55'' x 9' 10.11'' | |

| Weight PTO machine (std model) | kg/lbs | 6000 kg / 13228 lbs |

EXTRAS AND CONFIGURATIONS

RADIO REMOTE CONTROL

DEFERRIZATION

OUTLET GRID

AUTOMATIC TRASLATION

DISCHARGE BELT

Discharge belt, to obtain betterquality chips

FEEDER WITH GRIPPERS

Other extras and configurations

- TRACKS

Tracks to drive the machine in roush terrain

- REVERSIBLE FANS FOR RADIATOR CLEANING

Reversible fans for radiator cleaning, to clean the motor radiator and save fuel

TECNOLOGIE

INFORMATION REQUEST

Electric motor

Electric motor Power take off tractor

Power take off tractor Autonomous motor

Autonomous motor

1000 x 350 mm / 3' 3.37'' x 13.78''Maximum inlet passage

780 mm / 30.71''Chopping chamber diameter

Electric motor

Electric motor Power take off tractor

Power take off tractor Autonomous motor

Autonomous motor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US