REDLINE

HOME / REDLINE / CUT AND SPLIT / TLA 18 - TLA 20 - TLA 22

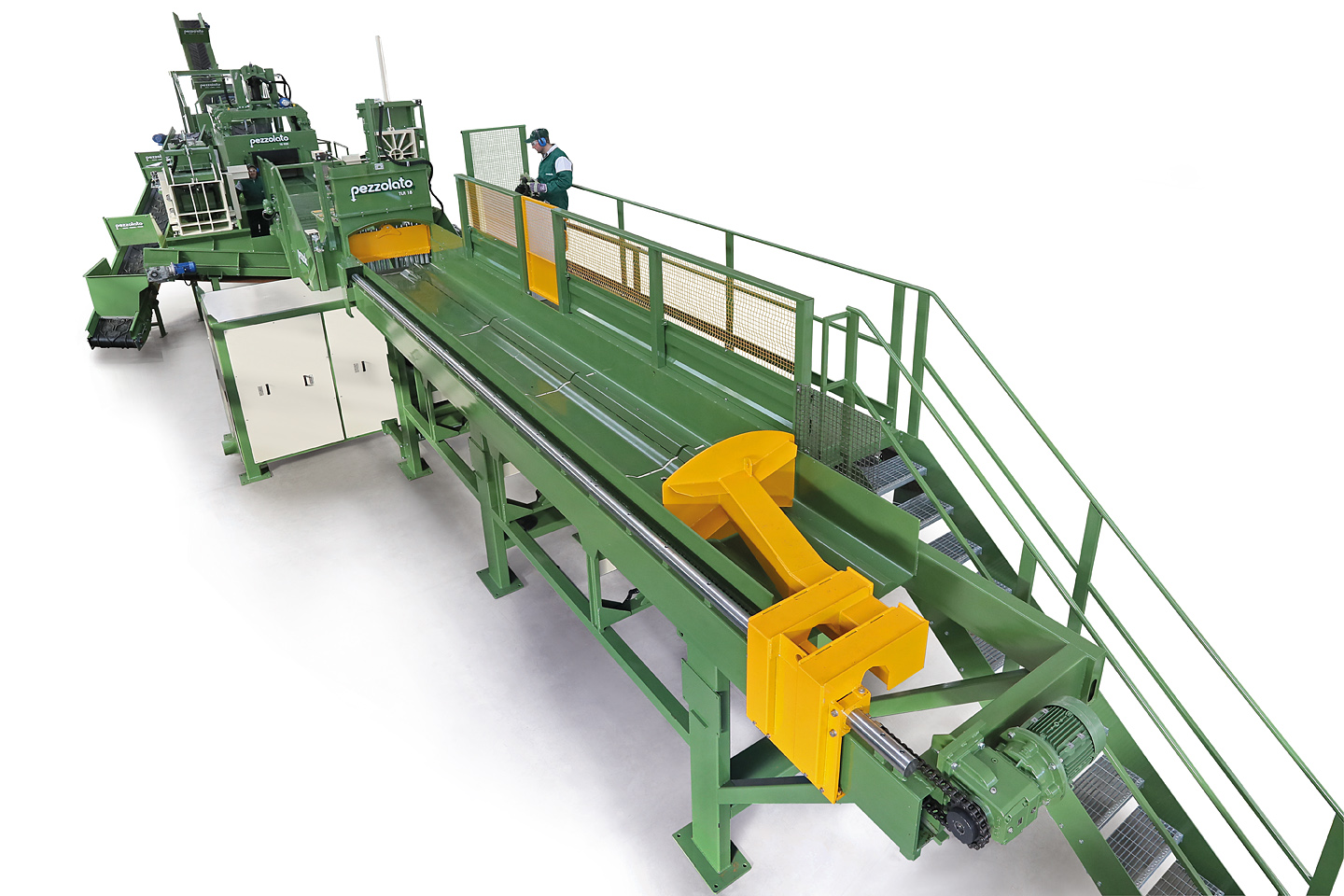

TLA 18 – TLA 20 – TLA 22

TLA 18 – TLA 20 – TLA 22

REDLINE Cut and Split Firewood disc processors with independent wood splitter

Firewood disc machines TLA, are the result of the technological development since the 80s, when Pezzolato started to produce the first firewood processors with high production capacity.

This machine is conceived to process mixed wood with different diameters and lengths.

From the control panel the operator can choose the cutting length, manually or in automatic; he can also operate the log loader.

After cutting, the logs fall in a cumulating S-shaped conveyor with closed meshes, which transfers them in front of the wood splitter.

Two operators guarantee the machine highest productivity. One operator only, who cuts first and then splits, obtains anyway a good production.

All machines are provided with all safety devices in compliance with the current regulations. It allows processing wood in a reliable, safe and effective way and guarantees high production capacity.

| TECHNICAL DATA | TLA 18 – TLA 20 – TLA 22 | |

|---|---|---|

| Disc diameter | mm | 1800 (TLA18) - 2000 (TLA 20) - 2200 (TLA22) |

| Disc diameter | ft | 5' 10.87'' (TLA18) - 6' 6.74'' (TLA 20) - 7' 2.61'' (TLA22) |

| Maximum log diameter | mm | 710 (TLA18) - 780 (TLA 20) - 850 (TLA22) |

| Maximum log diameter | in | 27.95" (TLA18) - 30.71'' (TLA 20) - 33.46'' (TLA22) |

| Feeding channel width | mm/ft | 1000 / 3' 3.37'' |

| Maximum height of cutting | mm | 3400 |

| Electric motor power | kW | 75/90 (TLA18) - 110/132 (TLA 20) - 110/132 (TLA22) |

EXTRAS AND CONFIGURATIONS

CONTROL PANEL / COMPUTER

Tested electronic control systems guarantee fast working cycles, optimize the machine production capacity and efforts.

CLEANING ROLLERS

Cleaning rollers on conveyors, to separate barks, sawdust and wood blocks.

RAISED PLANT

Raised plant, for easy maintenance and cleaning.

MULTIFOLDS GRID

Multifolds grid, further to the 2+4+6 folds grid.

C-SHAPED LOG SEPARATING SYSTEM

C-shaped log separating system: by pushing arms, steps with alternated movement, according to the logs to be processed

CYCLON ASPIRATOR

Cyclon Aspirator, big-pieces trap and collecting system in “big bag” sacks. As an alternative, single aspirator to remove sawdust from the machine.

DISCHARGE CONVEYORS

6 up to 15 m discharge conveyors, height hydraulically adjustable, manually or hydraulically orientable.

RUBBER BELT CONVEYOR

Rubber belt conveyor to transport the cut logs to the splitter

Loading dampers

Loading dampers to process big size logs. Shock abosrbers.

Hydraulic wood clamping

It works either with bundles and with logs

PALLET WOOD PACKER

Pallet wood packer, to pack cut and split wood for pallet transportation and stock.

LOG LOADER

The best loader is provided according to the wood to be processed.

Other extras and configurations

- HEATERS

LCD and hydraulic oil heaters for machines that works under 0°C

- TAILOR MADE CONFIGURATIONS

Tailor made configurations, to install plants in narrow places.

- WOODSPLITTER ENERGY RECOVERING SYSTEM

Woodsplitter energy recovering system, to speed up the working cycle

- EXTRA SPLITTING UNITS

Extra splitting units, to improve the plant productivity or to refine logs

- AUTOMATIC GRID CENTERING DEVICE

With Trunk diameter measuring sensor and grid positioner.

- PHOTOCELLI PROTECTIVE DEVICE

Photocell protection device for speeding up loads with dual boot, pedal and push-button system.

- S-SHAPED BAND

S-shaped band to transfer and cumulate up to 2 m3 of cut wood. Available in extra long version as well, to contain more wood

- CONVEYOR BELT

Conveyor belt with PVC or rubber band with loading 2.20 m or 5 m heigth (foldable for transport).

TECNOLOGIE

"POWER BAND" TRANSMISSION BELTS

INFORMATION REQUEST

Electric motor

Electric motor

1800 - 2000 - 2200 mm / 5' 10.87'' - 6' 6.74'' - 7' 2.61''Disc diameter

710 - 780 - 850 mm / 27.95''-30.71''-33.46''Maximum log diameter

75/90 - 110/132 - 110/132 kWElectric motor power

Electric motor

Electric motor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US