REDLINE

HOME / REDLINE / CUSTOMIZED EQUIPMENTS / SPECIAL FIREWOOD EQUIPMENT TO PRODUCE WOOD CHARCOAL

SPECIAL FIREWOOD EQUIPMENT TO PRODUCE WOOD CHARCOAL

SPECIAL FIREWOOD EQUIPMENT TO PRODUCE WOOD CHARCOAL

REDLINE Customized equipments

SPECIAL EQUIPMENT FOR THE PROCESSING OF MINIMUM 570 CUBIC METERS OF FIREWOOD FOR WOOD CHARCOAL (BBQ) PRODUCTION

Designed according to the customer’s needs: producing firewood industrially and semi-automatically from hard wood with variable diameters 50 ÷ 590 mm (1.97” ÷ 23.23”) and with lengths up to 6 m (19′ 8.22”)

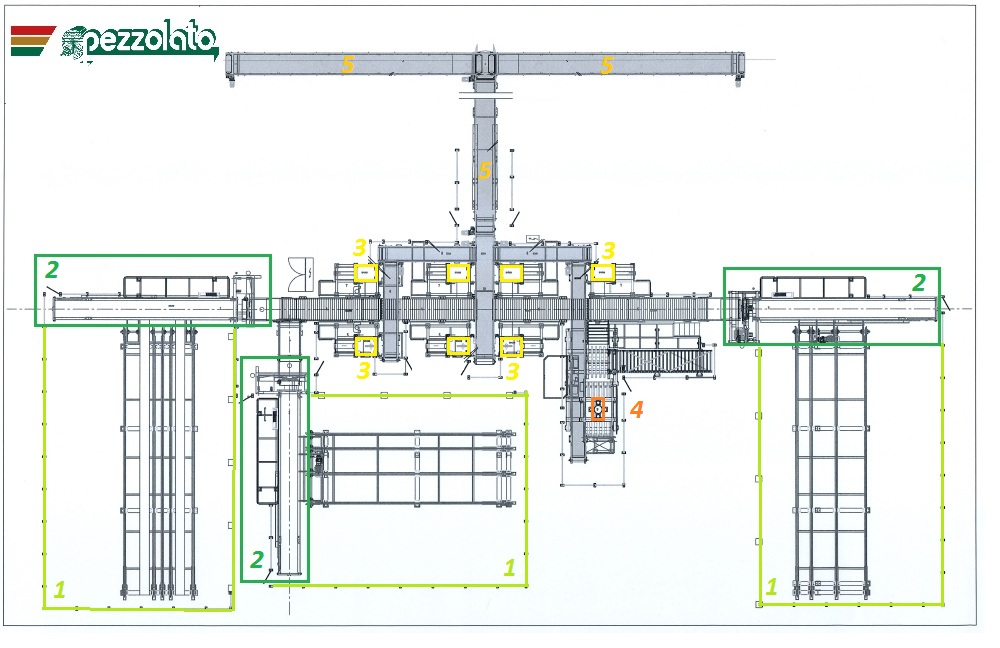

The equipment presents 5 main units:

1) n. 3 logs loading systems to feed the cut group;

2) n. 3 cutting units TLA 15;

3) n. 7 horizontal splitting stations with manual introduction;

4) n. 1 automatic vertical splitting station TB 900 (for bigger wood blocks);

5) evacuation system for the output product and feeding system towards the production of coal.

POS. 1 Logs loading systems

The equipment is equipped with three loaders for the handling of logs up to a length of 6 meters (19′ 8.22”). They have a C-shaped log separating system which transfers the material into the feeding conveyor of the cut group TLA 15. The complete introduction system is manually operated by the operator of the TLA 15 group during the automatic cut cycle.

POS. 2 Cutting units TLA 15

Totally automatic, cut disc with diameter 1500 mm (4′ 11.06”), feeding conveyor width 800 mm (31.5”) and length 6.8 meters (22′ 3.72”); designed to process logs with diameters up to 600 mm (23.62”) and big bundles of mixed wood; equipped with loading dampers and log turners; the presence of the operator is necessary to monitor the whole process which is automatic and optimize the introduction.

POS. 3 Horizontal splitting units

N. 4 horizontal splitting units, pushing strength 20 tons; grid with automatic centering device, equipped with a fixed 2/4/6 fold sectors.

N. 3 horizontal splitting units, pushing strength 32 tons; grid with automatic centering device, equipped with a fixed 2/4/6 fold and an interchangeable 16 fold sectors.

POS. 4 Vertical splitting unit TB 900

Vertical automatic splitting unit TB 900, pushing strength 40 tons, no operator is required.

POS. 5 Evacuation system for the output product and feeding system towards the production of coal

A series of conveyor bands collects the cut and split wood processed by the splitting units and handles this material towards the feeding system for the production of coal.

The minimal performance of this equipment is 570 cubic meters/day (160 bulk cords/day) with ten operators (three of them operating the cutting units TLA15) to mantein on function the wood charcoal gasification units.

| TECHNICAL DATA | SPECIAL FIREWOOD EQUIPMENT TO PRODUCE WOOD CHARCOAL | |

|---|---|---|

| NR. 3 TLA 15 CUTTING UNITS | ||

| Electric motor power | kW/hp | 55 kW / 74 hp |

| Disc with hard metal tipped teeth diameter | mm/ft | 1500 mm / 4' 11.06'' |

| Maximum log diameter | mm/in | 590 mm / 23.23'' |

| Feeding channel width | mm/in | 800 mm / 31.5" |

| Maximum cutting length | mm/in | 710 mm / 27.95" |

| NR. 4 HORIZONTAL SPLITTING STATION | ||

| Splitting force | ton | 20 |

| Hydraulic splitting grid/wedge | folds | 2+4+6 |

| NR. 3 HORIZONTAL SPLITTING STATION | ||

| Splitting force | ton | 32 |

| Hydraulic splitting grid/wedge | folds | 6+16 |

| TB 900 SPLITTING STATION | ||

| Maximum splitting diameter | mm/in | 900 mm / 35.43'' |

| Splitting force | ton | 40 |

EXTRAS AND CONFIGURATIONS

TECNOLOGIE

"POWER BAND" TRANSMISSION BELTS

INFORMATION REQUEST

Electric motor

Electric motor

1500 mm / 4' 11.06'' (Nr. 3 TLA 15)Disc diameter

590 mm / 23.23''Maximum log diameter

570 m³ x day / 160 bulk cords x dayProduction capacity

Electric motor

Electric motor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US