PTH 1400/1000

PTH 1400/1000

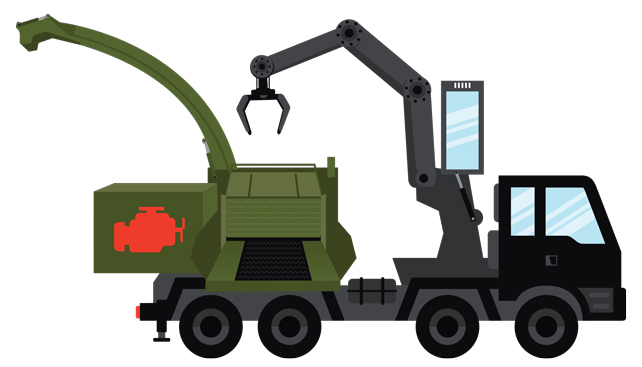

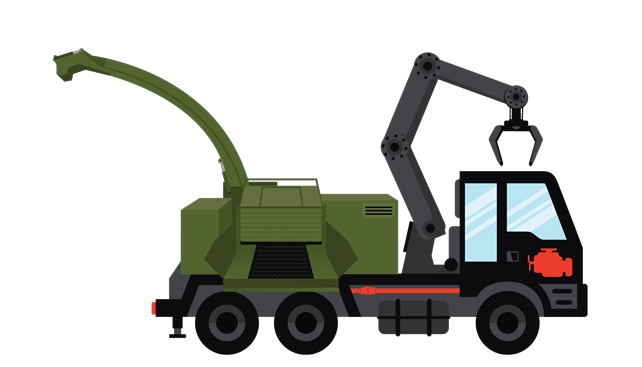

GREENLINE Chippers Camion motor - HackerTRUCK

The industrial chipper PTH 1400/1000 HACKERTRUCK is one of the heavy duty machines within Pezzolato drum chippers, whose drum diameter measures 1000 mm (3′ 3.37”). Its feeding mouth is 1400 mm (4′ 7.12”) wide.

Able to produce over 300 m3 chips per hour, it guarantees high throughput.

The HACKERTRUCK series chippers are mounted on trucks with 3 or 4 axles and are characterised by high power and performance combined with great maneuverability and versatility.

In HACKERTRUCK chippers the drive system can use the same engine as the truck in order to eliminate an auxiliary one, so as to unburden the vehicle and to increase the manovrability.

They can be customised with many settings to make them more versatile to all working condition and are therefore appreciated by large contractors who have to move quickly on many different sites.

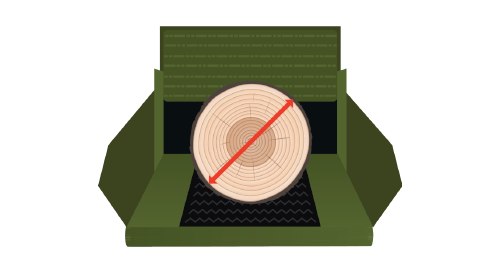

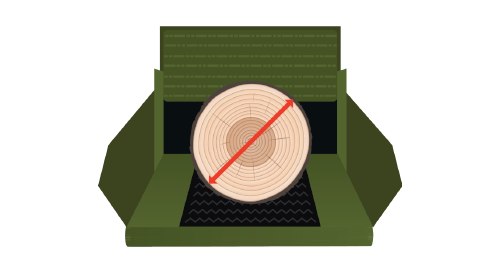

The Pezzolato solid drum, well-known for reliability, wear-resistance and no maintenance, has been designed to guarantee the best quality wood chips, either small or big dimensions.

It is staggered section type in order to distribute the machine’s effort equally, reducing vibrations, noise and consumption.

The sharp cut through the blades and the large drum’s inertia reduce the machine’s efforts and stress, thus confirming the well-known solidity of Pezzolato industrial chippers.

| TECHNICAL DATA | PTH 1400/1000 | ||

|---|---|---|---|

| Diesel engine power | hp/kW | 510/375 - 750/551 | |

| Max chipping diameter soft wood | mm/in | 800 mm / 31.50'' | |

| Max chipping diameter hard wood | mm/in | 550 mm / 21.65'' | |

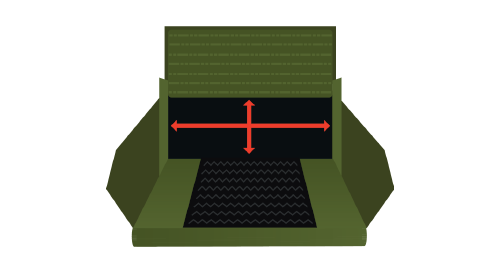

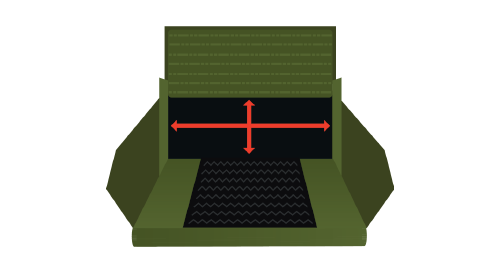

| Maximum inlet passage | mm/ft | 1400 x 1100 mm / 4' 7.12'' x 3' 7.31'' | |

| Knives | n° | 5/6/10/12 | |

| Hourly throughoutput | m³/h | over 300 | |

| Drum diameter | mm/ft | 1000 mm / 3' 3.37'' | |

| Drum width | mm/ft | 1400 mm / 4' 7.12'' | |

| Hooked steel feeding conveyor width | mm/ft | 1400 mm / 4' 7.12'' | |

| Hooked steel feeding conveyor lenght | mm/ft | 2200 mm / 7' 2.61'' | |

| Hopper width | mm/ft | 2200 mm / 7' 2.61'' |

EXTRAS AND CONFIGURATIONS

HYDRAULIC FAN

The chips expulsion fan with continuous speed regulation allows adjusting the speed to the real necessities, decreasing energy need.

FORESTRY CRANES

Forestry cranes, with or without cabin, in customised configuration

DISCHARGE BELT

Discharge belt, to obtain betterquality chips

RECOVERING COLLECTING SCREWS

Recovering collecting screws, under the lower feeding roller, to keep the working area clean

REDUCED TRACK

Reduced track improves handling characteristics allowing possibly to travel those forest tracks not normally accessible by vehicles of this type.

MACHINE SET UP ON A TRUCK WITH 3 AXLES

RADIATOR INCREASED

Radiator for the coolant increased to reduce overheating of the motor and positionated externally to allow for a quick cleaning while working in a stationary position.

MACHINE SET UP ON A TRUCK WITH 4 AXLES

LCD COLOR DISPLAY AND EXPECTIVE CAMERAS

LCD color Display and inspection camera

SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

TRASMISSION GROUP

It transfers the truck power to the chipper with maximum torque of 2500 Nm

SPECIAL DRUM

Special drum to produce extra size chips: it improves production capacity 15% and reduces fuel consumption 16%

HYDRAULICALLY BENDING HOPPER

Hydraulically bending hopper, to chip very long wood

SUPPLEMENTARY TUBE

Supplementary tube to eject the chips in front of the cab of the truck in limited spaces.

C-SHAPED WOOD-SPLITTER

C-shaped wood-splitter with or without chain saw

Other extras and configurations

- BALCK-BOX CONTROL

Black-box control to capture data on site and transfer directly to a central information point

- HYGROMETER

Hygrometer to continuously measure the humidity of the wood chips and allow an immediate qualitative assessment of the product.

- REVERSIBLE FANS FOR RADIATOR CLEANING

Reversible fans for radiator cleaning, to clean the motor radiator and save fuel

TECNOLOGIES

INFORMATION REQUEST

510-750 Hp / 375-551 kW Truck engine power

800 mm / 31.50'' mm Maximum chipping diameter

1400 x 1100 mm / 4' 7.12'' x 3' 7.31'' Maximum inlet passage

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US