PTH 30.50

PTH 30.50

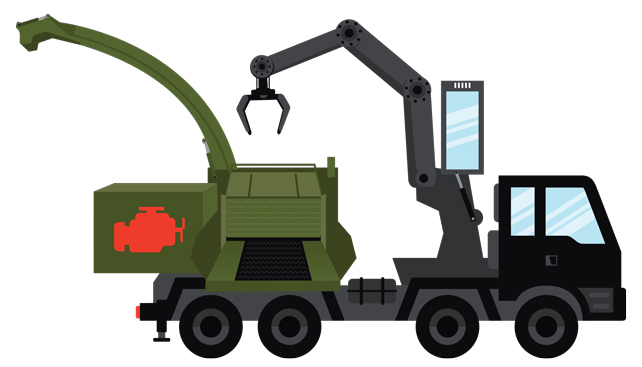

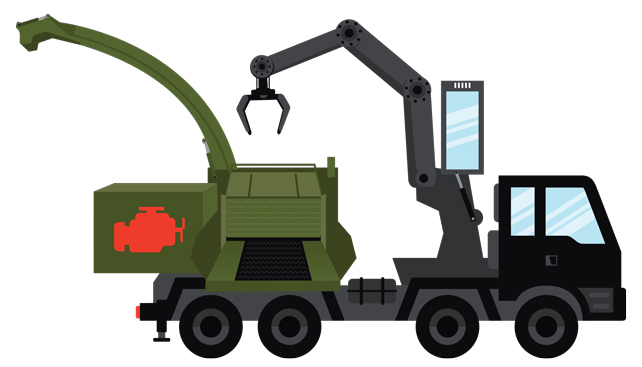

GREENLINE Chippers Autonomous motor

Designed to ensure an easier use for the operator and minimize maintenance costs, it is appreciated for the typically robust structure of Pezzolato chippers, ensuring reliability and excellent performance.

It is the ideal chipper both for the maintenance of greenery (thanks to the large feed hopper, is able to easily insert even bulky material), both for the wood and forest maintenance technician who needs, in addition to disposing of to reduce volumes and prevent forest fires, of produce quality wood chips.

A stationary version with an electric motor is also available for carpentry or pellet producers. It can be built in two versions: for manual feeding or for feeding by mechanical means.

In the first case, the chipper is equipped with a sturdy safety bar that guarantees the operator present on the machine a safe use of the machine, while in the mechanical supply set-up the operator has a remote control to manage the main functions from a distance.

The main wear parts are specially designed for easy replacement, as well as having a low cost.

| TECHNICAL DATA | PTH 30.50 | ||

|---|---|---|---|

| Diesel engine power | Hp/kW | 99/74 | |

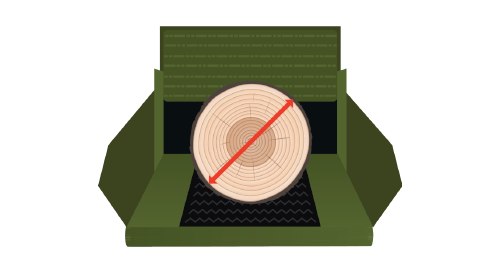

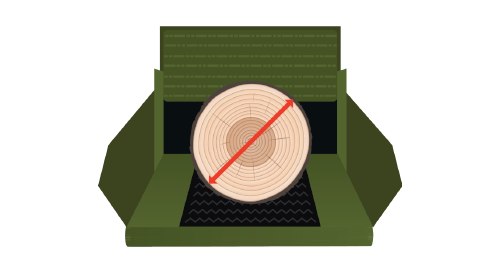

| maximum chipping diameter | 300 | ||

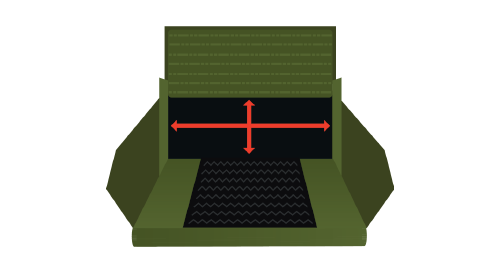

| Drum width | mm/in | 500 | |

| Knives | n° | 3 | |

| Hourly throughoutput | m³/h | 10 ÷ 16 | |

| Maximum Inlet Passage | mm/in | 500 x 300 | |

| Drum diameter | mm/in | 520 | |

| Upper rollers | n° | 500 | |

| Weight | kg/lbs | 3500 |

EXTRAS AND CONFIGURATIONS

Sieving grids

Sieving grids for chip calibration with differerent sizes, easy to replace

NO STRESS electronic device

NO STRESS electronic device, available on all standard machines, automatically regulates the in-feed of material according to the available power

Radio remote control

Radio remote control, to manage the chippers main activities at a distance

Electronic controller with 5" "touch screen" panel

Other extras and configurations

- Wear–resistant Hardox metal sheets for discharging fan

INFORMATION REQUEST

Autonomous motor

Autonomous motor Power take off tractor

Power take off tractor

75/55 Hp/kW Diesel engine power

300 mm Maximum chipping diameter

500x300 mm Maximum inlet passage

Autonomous motor

Autonomous motor Power take off tractor

Power take off tractor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US