PTH 700

PTH 700

GREENLINE Chippers Autonomous motor

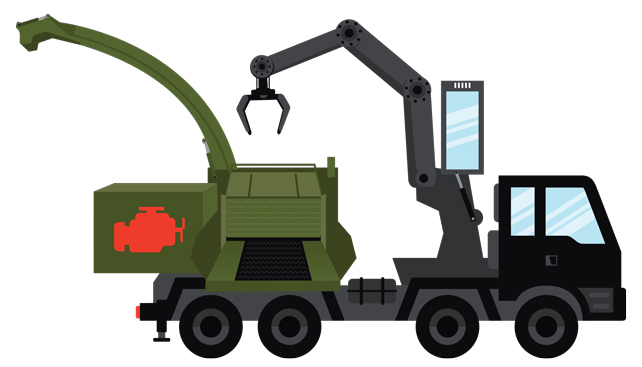

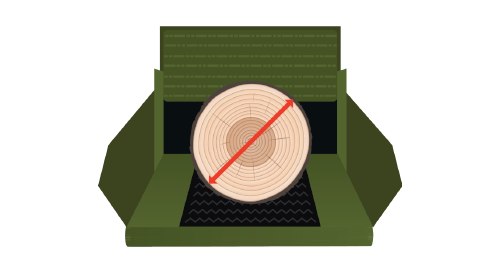

PTH 700 is one of the medium power machines within Pezzolato drum chippers, whose drum diameter measures 660 mm (25.98”).

Its feeding mouth is 640 mm (25.20”) wide.

Able to produce up to 80 m³ chips per hour, it guarantees high throughput.

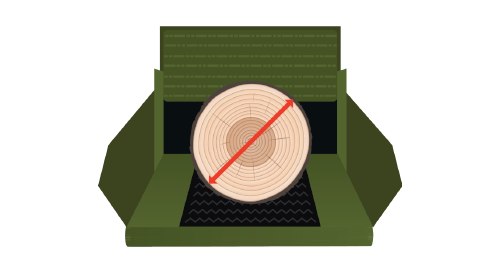

The design of the conical hopper (without bottlenecks that tend to trap the material), combined with a catenary system able to move the material directly to the drum, allows feeding of bulk material.

The large fan (1250 mm) mounted directly on the drum shaft is able to work at a low speed (less than 600 revs) to help reduce dust and increase wood chip quality.

Each standard installation includes a single axis trailer which provides compactness and increases agility and manoeuvrability in tight spaces.

The wear parts of all machines are cost effective and simple to replace in short maintenance times.

The drum with cuttinng system interchangeable where required, makes these chippers ideal for the production of wood chips used with domestic boilers, large power plants or gasifiers.

The integrated computer suggests any ordinary and extraordinary maintenace operations to be performed according to the manufacturer’s maintenance.

| TECHNICAL DATA | PTH 700 | ||

|---|---|---|---|

| Diesel engine power | hp/kW | JOHN DEERE 205 - 153 | |

| Max chipping diameter soft wood | mm/in | 500 mm / 19.69'' | |

| Max chipping diameter hard wood | mm/in | 350 mm / 13.80'' | |

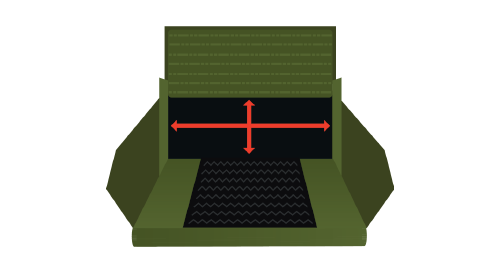

| Maximum inlet passage | mm/in | 640 x 600 mm / 25.20 x 23.62'' | |

| Knives | n° | 3 | |

| Hourly throughoutput | m³/h | until 80 | |

| Drum diameter | mm/in | 660 mm / 25.98'' | |

| Drum width | mm/in | 640 mm / 25.20'' | |

| Hooked steel feeding conveyor width | mm/in | 640 mm / 25.20'' | |

| Hooked steel feeding conveyor lenght | mm/ft | 2200 mm / 7' 2.61'' | |

| Weight | kg/lbs | 8200 kg / 18078 lbs |

EXTRAS AND CONFIGURATIONS

LOW-OR HIGH-SPEED TOWING TRAILER

Low or high-speed towing trailer, with air or hydraulic brakes

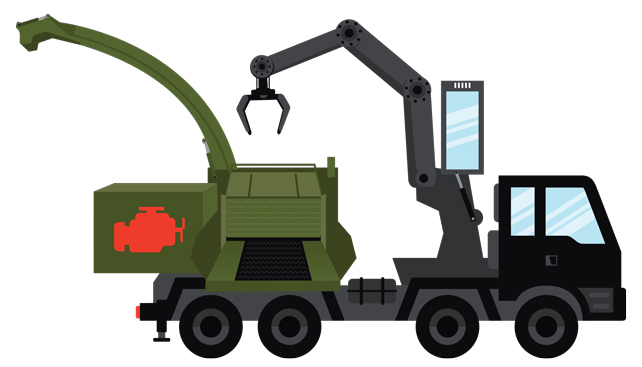

FORESTRY CRANES

Forestry cranes, with or without cabin, in customised configuration

TRACKS

Tracks to drive the machine in roush terrain

PIEDI IDRAULICI AUTO SOLLEVABILI

Telescopic legs enable transportation of the chipping unit on several vehicles

HOOK-LIFT SYSTEM

Hook-lift system

SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

BENDING HOPPER (STANDARD)

Bending hopper (2°), to chip very long wood

HYDRAULIC TRACTION

Hydraulic traction, to easily move the machine in impervious paths

C-SHAPED WOOD-SPLITTER

C-shaped wood-splitter with or without chain saw

RADIO REMOTE CONTROL

Radio remote control to manage the chipper’s main activities at a distance

Other extras and configurations

- MOUNT ON FORESTRY TRAILERS AND FORWARDERS

PTO and Diesel Engine powered chippers are available to mount on Forestry trailers and forwarders.

- 3 POINT HITCH ATTACHMENT

3 point hitch attachment, to compact the machine and work in narrow places

- INTEGRATED CONTAINER

Integrated container, with hydraulic pivoting, to collect chips where there is difficult access for other vehicles

- COLLAPSIBLE COUNTER-BLADE

Collapsible counter-blade secured with shear bolts

- DRIVE-LINE HOPPER

Drive-line hopper, to feed the machine with voluminous material

INFORMATION REQUEST

Autonomous motor

Autonomous motor Power take off tractor

Power take off tractor

JOHN DEERE 149 KW – 200 Hp Diesel engine power

500 mm / 19.69'' Maximum chipping diameter

640 x 600 mm / 25.20 x 23.62'' Maximum inlet passage

Autonomous motor

Autonomous motor Power take off tractor

Power take off tractor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US