PTH 500

PTH 500

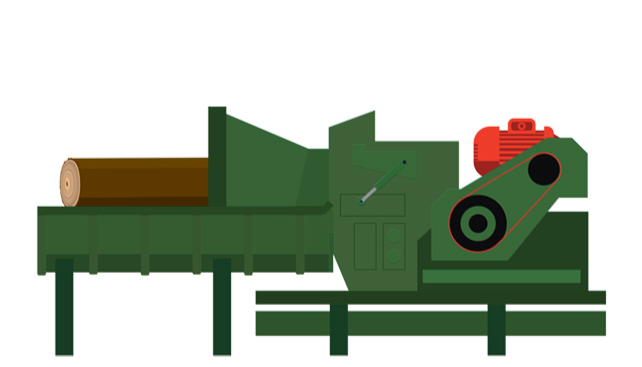

GREENLINE Chippers Electric motor

The smaller model of the 660 series of Pezzolato drum chippers.

This particular machine is ideal for those who produce wood chips as fuel for domestic heating systems, for agricultural tourism, hotels, greenhouses, schools, or for those who simply need to reduce the debris from pruning.

It can be fed manually or using a mechanical loader.

The entry of material is facilitated by a feed conveyor inside the hopper (on request a second feed conveyor can be supplied for the hopper tipper).

The combined action of the belt and upper roller facilitates the introduction of bulk material, even using mechanical loaders.

Routine maintenance and the replacement of knives can be perfermed extremely quickly and easily thanks to the “total” lifting of the feed roller.

| TECHNICAL DATA | PTH 500 | ||

|---|---|---|---|

| Electric motor power | kW/hp | 55-75 | |

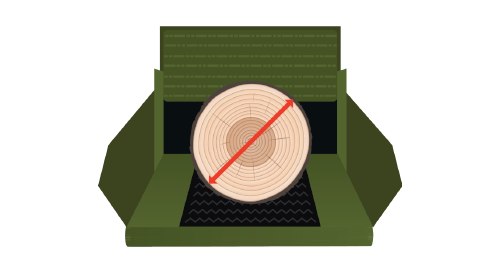

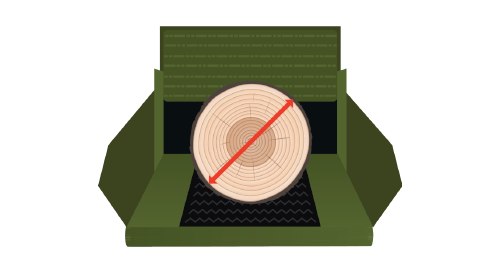

| Max chipping diameter soft wood | mm/in | 400 mm / 15.75'' | |

| Max chipping diameter hard wood | mm/in | 300 mm / 11.81'' | |

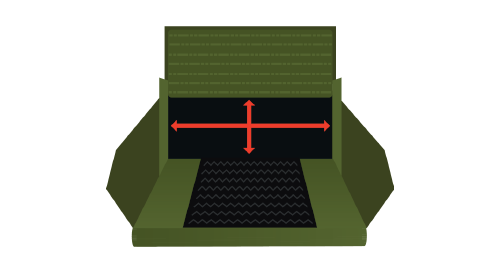

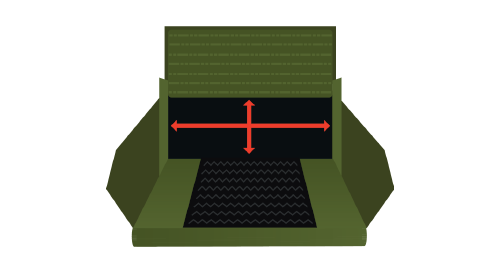

| Maximum inlet passage | mm/in | 500 x 400 mm / 19.69 x 15.75'' | |

| Knives | n° | 2 - 3 | |

| Hourly throughoutput | m³/h | 20 ÷ 30 | |

| Drum diameter | mm/in | 660 mm / 25.98'' | |

| Drum width | mm/in | 480 mm / 18.90'' | |

| Hooked steel feeding conveyor width | mm/in | 500 mm / 19.69'' | |

| Hooked steel feeding conveyor lenght | mm/in | 550 mm / 21.65'' | |

| Cutting depth adjustment | mm | 15 |

EXTRAS AND CONFIGURATIONS

HOPPER WITH FEEDING CHAIN

Hopper with feeding chain, hydraulic drive, to increase the aggressiveness of the machine feeding.

Electronic controller with 5" "touch screen" panel

RADIO OR CABLE REMOTE CONTROL

Radio or cable remote control, to manage the chipper's main activities at a distance

SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

DISCHARGE BELT

Discharge belt, to obtain betterquality chips

SECURITY BAR

Removable security bar, for hand feeding

Other extras and configurations

- Wear–resistant Hardox metal sheets for discharging fan

- CHARGING ROLLERS

Charging rollers to ease the introduction of certain types of wood for stationary machines

- NO STRESS ELECTRONIC DEVICE

NO STRESS electronic device, available on all standard machines, automatically regulating the in-feed of material according to the available power

- HYDRAULIC ORIENTATION DISCHARGE TUBE

Hydraulic orientation (deflector rotation and direction) discharge tube

INFORMATION REQUEST

55-75 kW Electric motor power

400 mm mm Maximum chipping diameter

500x550 mm Maximum inlet passage

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US