REDLINE

HOME / REDLINE / CUSTOMIZED EQUIPMENTS / SPECIAL FIREWOOD EQUIPMENT FOR U.S.A. LARGE RETAILERS

SPECIAL FIREWOOD EQUIPMENT FOR U.S.A. LARGE RETAILERS

SPECIAL FIREWOOD EQUIPMENT FOR U.S.A. LARGE RETAILERS

REDLINE Customized equipments

SPECIAL EQUIPMENT FOR FIREWOOD PRODUCTION – GEORGIA (U.S.A.)

Designed according to the customer’s needs: producing firewood industrially and semi-automatically from hard wood with variable diameters 100 ÷ 700 mm (from 3.94” to 27.56”) and with lengths up to 21 m (68′ 10.77”).

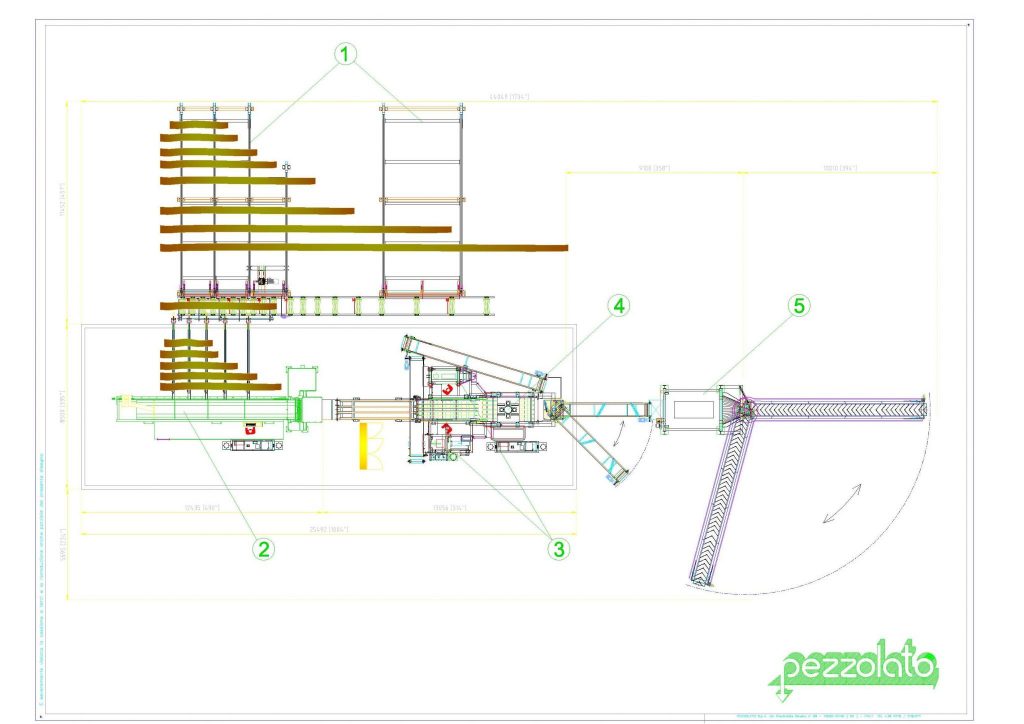

The equipment presents 5 main units:

1) Logs loading system and measure sectioning according to cut group;

2) Cut group TLA 18;

3) Horizontal splitting stations with manual introduction;

4) Automatic vertical splitting station TB 900 (for bigger wood blocks);

5) Cleaning system for the processed logs and evacuation of the final product.

POS. 1 Logs loading system

The equipment is equipped with a first loader for the handling of logs up to a length of even 21 m (68′ 10.77”). This first loader has a C-shaped log separating system which transfers the material to a roller system with chain saw bar for the sectioning of logs to the right measure for the cut group TLA 18. The material, ready for the automatic cut, is finally transferred to a second loader, with the function of collecting point. The complete logs loading system (first loader, roller system, saw bar, second loader) is manually operated by the operator of the TLA 18 group during the automatic cut cycle.

POS. 2 Cut group TLA 18

Totally automatic, cut disc with diameter 1800 mm (5′ 10.87”), feeding conveyor width 1 meter (3′ 3.37”) and length 6.8 meters (22′ 3.72”); designed to process logs with diameters up to 700 mm (27.56”) and big bundles of mixed wood; equipped with loading dumpers and log turners; the presence of the operator is necessary to monitor the whole process which is automatic and optimize the introduction.

POS. 3 Horizontal splitting stations with manual introduction;

Horizontal splitting unit, splitting force 40 ton for logs with diameters up to 550 mm (21.65”); grid with automatic centering device, equipped with a fixed 2/4/6 fold sectors and an interchangeable 16 fold sector. Horizontal splitting unit with a special grid with squares Genius Wedge, splitting force 35 ton for wood logs with diameters up to 480 mm (18.9”).

POS. 4 Automatic vertical splitting station TB 900

Vertical automatic splitting unit TB 900, splitting force 40 ton, no operator is required.

POS. 5 Cleaning system for the processed logs and evacuation of the final product.

A rotating drum screener, with noise reduction system, cleans the processed logs by separating chips, barks and sawdust. The output conveyor, hydraulically adjustable, piles the material up till 5.50 m (18′ 0.54”) of height within an operation range of 110°.

The performance of this equipment is more than 200 cubic meters (56 bulk cords)/shift with only three operators.

| TECHNICAL DATA | SPECIAL FIREWOOD EQUIPMENT FOR U.S.A. LARGE RETAILERS | |

|---|---|---|

| TLA 18 CUTTING UNIT | ||

| Electric motor power | kW/hp | 75 kW / 100 hp |

| Disc with hard metal tipped teeth diameter | mm/ft | 1800 mm / 5′ 10.87'' |

| Maximum log diameter | mm/in | 700 mm / 27.56'' |

| Feeding channel width | mm/ft | 1000 mm / 3' 3.37'' |

| Maximum cutting length | mm / inches | 710 mm / 27.95'' |

| HORIZONTAL SPLITTING STATION | ||

| Splitting force | ton | 40 |

| Maximum splitting diameter | mm/in | 550 mm / 21.65'' |

| Maximum splitting length | mm/in | 710 mm / 27.95'' |

| Hydraulic splitting grid/wedge | folds | 2+4+6+16 |

| GENIIUS WEDGE SPLITTING STATION | ||

| Splitting force | ton | 35 |

| Maximum splitting diameter | mm/in | 480 mm / 18.9'' |

| Maximum splitting length | mm/in | 550 mm / 21.65'' |

| Hydraulic splitting grid/wedge | folds | Genius wedge |

| TB 900 VERTICAL SPLITTING STATION | ||

| Splitting force | ton | 40 |

| Maximum splitting diameter | mm/in | 900 mm / 35.43'' |

| Maximum splitting height: | mm/in | 500 mm / 18.69'' |

EXTRAS AND CONFIGURATIONS

TECNOLOGIE

"POWER BAND" TRANSMISSION BELTS

INFORMATION REQUEST

Electric motor

Electric motor

1800 mm / 5' 10.87''Disc diameter

700 mm / 27.56''Maximum log diameter

200 m³ x shift / 56 bulk cords x shiftProduction capacity

Electric motor

Electric motor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US