REDLINE

HOME / REDLINE / CUT AND SPLIT / TL-K650

TL-K650

TL-K650

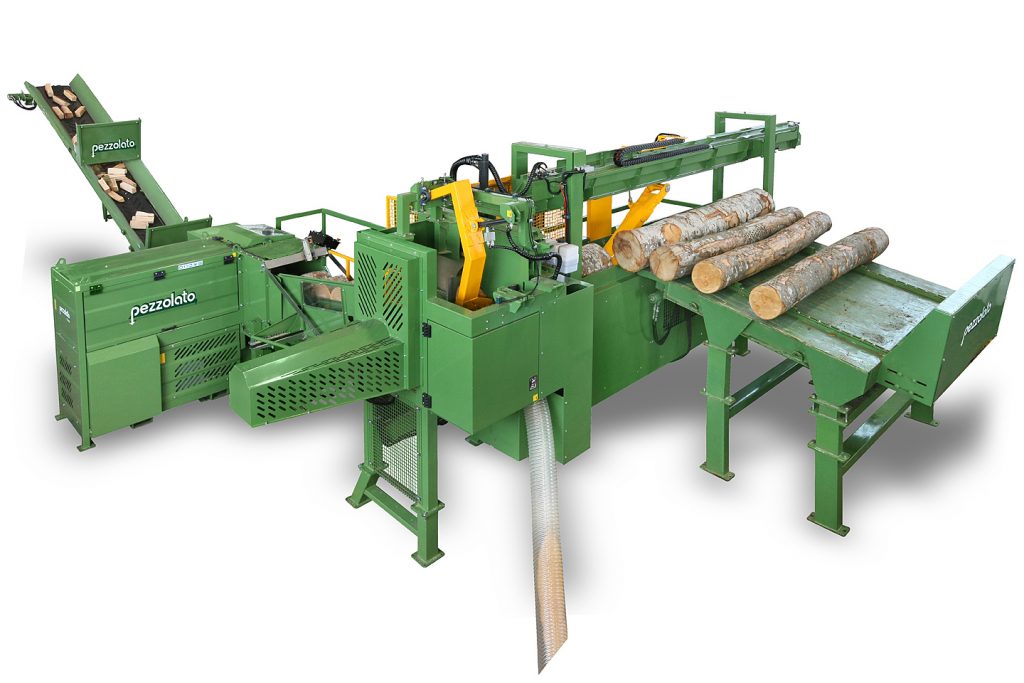

REDLINE Cut and Split Firewood disc processors with integrated wood splitter

This industrial plant consists of the TL650 cutting system and a KX650 or KV700 automatic log splitter.

Introduced in 2022, it was designed to be a complete cutting-splitting system of small dimensions, but capable of processing large logs (diameter up to 650 mm) and splitting logs, producing firewood with a programmable section.

This plant is equipped with an automatic process for the elimination of waste during the cutting phase, requires a limited energy supply (52 kW) and allow optimisation of the cycle time in relation to the size of the logs to be produced. A solution that guarantees high productivity with a only one operator.

TL650 – Cutting station

The TL650 cutting system, designed to work in semi-automatic mode with a single operator, is equipped with a SUPERCUT Hultdins 800mm saw unit with professional .404 chain, which ensures always precise cuts.

The log is pushed from behind by a feed arm. Adjustment of the cutting length (variably adjustable with a minimum end length of 220 mm) for logs up to a maximum diameter of 650 mm is carried out electronically, with the cut being ejected and the log then processed without residue or split by computer – an optimised method without a cut.

PLC control is optional to make the processing totally automatic and allow remote assistance via Ethernet router. With the PLC option, it is possible to install a hydraulic Rear log-pusher to support the last two cuts of the log, binding their correct positioning.

Another option: the lifting wood-pusher, which allows to anticipate as much as possible the loading of the new log to be cut in order to optimize the time and efficiency of the machine. The loading channel of the TL650 is equipped with two loading dumpers that support the fall of the logs in the cutting position. There is a spacious platform for the operator, with safety doors to protect the operating areas. The cutting unit is powered by a 30 kW electric motor.

KX650 – Splitting station

The K650 splitting station is equipped with PLC control, so is possible always work in automatic mode. The section of firewood logs can be electronically adjusted with a minimum size of 50x50mm.

The mobile splitting wedge allows to split the log against a fixed barrier and to process logs of variable length from 200 to 500 mm, with automatic stroke adjustment and consequent reduction of the cycle time.

Last plus, but not least: the timing belt under the splitter wedge is made of steel to better resist wear and stress generated by splitting operations.

The machine has centralized automatic lubrication, which facilitates routine maintenance. The splitting unit is powered by a 22kW electric motor.

KV700 – Splitting station

The KV 700 splitting unit is equipped with two mobile and independent splitting wedges, positioned in a ‘V’ shape, which allow logs between 150 and 500 mm in length to be processed. The unit is powered by a 30 kW electric motor and each wedge has a thrust force of 16 tonnes. The cross-section of the split logs can be adjusted electronically and, thanks to the presence of a specific optional arm, it is possible to quickly convert firewood production to fire starters with a minimum cross-section of 20 x 20 mm.Last but not least: the log splitter feed belt is made of steel to better withstand wear and tear generated by splitting operations.

| TECHNICAL DATA | TL-K650 | |

|---|---|---|

| Maximum trunk diameter | mm/in | 650 |

| Splitting force | ton | 52 |

| Maximum Inlet Passage | mm | 3400 |

EXTRAS AND CONFIGURATIONS

TECNOLOGIE

INFORMATION REQUEST

Electric motor

Electric motor

650 Maximum log diameter

52 kWElectric motor power

Electric motor

Electric motor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US