PTH 1000/1000

PTH 1000/1000

GREENLINE Chippers Power take off tractor

PTH 1000/1000 is one of the heavy duty machines to chip big diameter logs within Pezzolato drum chippers, whose drum diameter measures 1000 mm (3′ 3.37”).

Its feeding mouth is 1000 mm (3′ 3.37”) wide.

Able to produce up to 220 m3 chips per hour, it guarantees high throughput.

The Pezzolato solid drum, well-known for reliability, wear-resistance and no maintenance, has been designed to guarantee the best quality wood chips, either small or big dimensions. It is staggered section type in order to distribute the machine’s effort equally, reducing vibrations, noise and consumption.

The sharp cut through the blades and the large drum’s inertia reduce the machine’s efforts and stress, thus confirming the well-known solidity of Pezzolato drum chippers.

The wear spare parts of all machines are cost effective and simple to replace in short maintenance times and cheap.

The integrated computer suggests any ordinary and extraordinary maintenace operations to be performed according to the manufacturer’s maintenance plan.

| TECHNICAL DATA | PTH 1000/1000 | ||

|---|---|---|---|

| Minimum tractor power | hp/kW | 250/149 | |

| Maximum power of the tractor | hp/kW | 600/388 | |

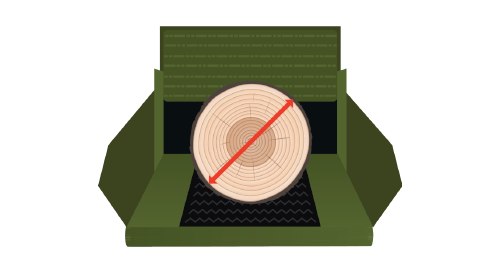

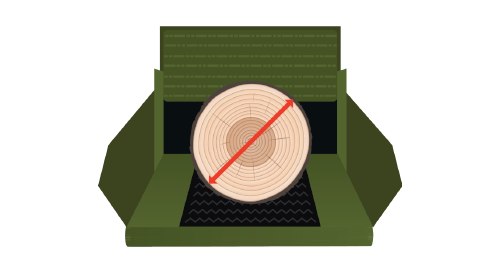

| Max chipping diameter soft wood | mm/in | 800 mm / 31.50'' | |

| Max chipping diameter hard wood | mm/in | 550 mm / 21.65'' | |

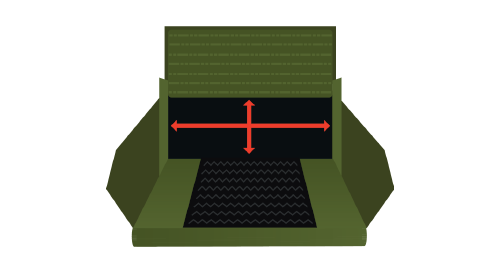

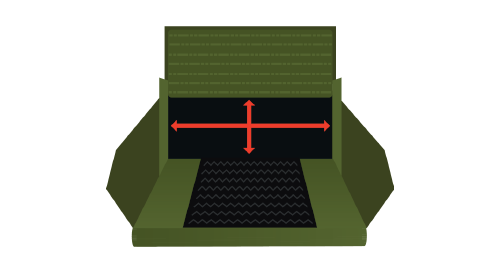

| Maximum inlet passage | mm/ft | 1000 x 1100 mm / 3' 3.37'' x 3' 7.31'' | |

| Knives | n° | 4 | |

| Hourly throughoutput | m³/h | until 220 | |

| Drum diameter | mm/ft | 1000 mm / 3' 3.37'' | |

| Drum width | mm/ft | 1000 mm / 3' 3.37'' | |

| Hooked steel feeding conveyor width | mm/ft | 1000 mm / 3' 3.37'' | |

| Hooked steel feeding conveyor lenght | mm/ft | 2200 mm / 7' 2.61'' | |

| Weight | kg/lbs | 16500 kg / 36376 lbs | |

| Hopper length | mm | 1800 |

EXTRAS AND CONFIGURATIONS

SPECIAL DRUM

Special drum to produce extra size chips: it improves production capacity 15% and reduces fuel consumption 16%

HYDRAULIC TRACTION

Hydraulic traction, to easily move the machine in impervious paths

C-SHAPED WOOD-SPLITTER

C-shaped wood-splitter with or without chain saw

HYDRAULIC FAN

The chips expulsion fan with continuous speed regulation allows adjusting the speed to the real necessities, decreasing energy need.

LOW-OR HIGH-SPEED TOWING TRAILER

Low- or high-speed towing trailer, with air or hydraulic brakes

DISCHARGE BELT

Discharge belt, to obtain betterquality chips

HOPPER EXTENSION

Hydraulically folding hopper extension, to easily introduce certain types of wood

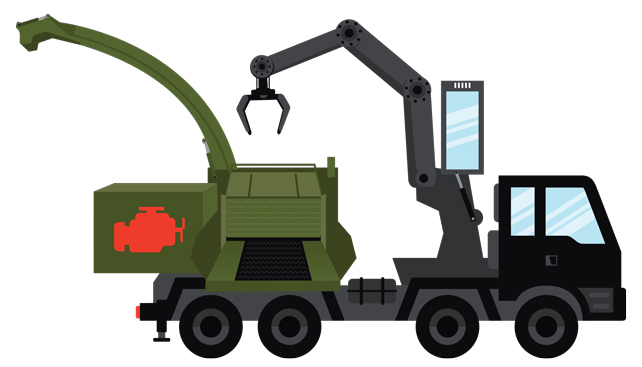

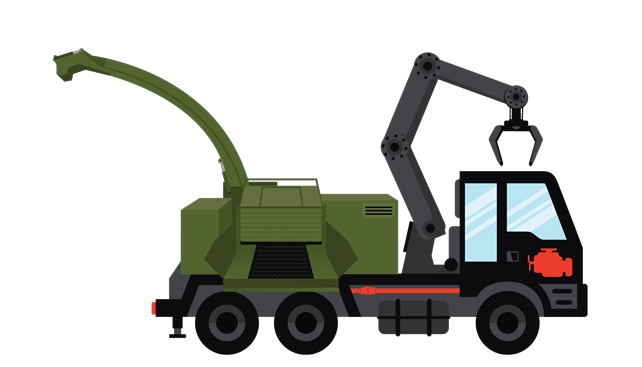

FORESTRY CRANES

Forestry cranes, with or without cabin, in customised configuration

RADIO REMOTE CONTROL

Radio remote control to manage the chipper’s main activities at a distance

RECOVERING COLLECTING SCREWS

Recovering collecting screws, under the lower feeding roller, to keep the working area clean

LCD COLOR DISPLAY AND EXPECTIVE CAMERAS

LCD color Display and inspection camera

SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

Other extras and configurations

- DRIVE-LINE HOPPER

Drive-line hopper, to feed the machine with voluminous material

- INTEGRATED CONTAINER

Integrated container, with hydraulic pivoting, to collect chips where there is difficult access for other vehicles

TECNOLOGIES

INFORMATION REQUEST

200 Hp / 149 kW Minimum required tractor power

800 mm / 31.50'' Maximum chipping diameter

1000 x 1100 mm / 3' 3.37'' x 3' 7.31'' Maximum inlet passage

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US