PTH 1000/820

PTH 1000/820

GREENLINE Chippers Autonomous motor

Medium-heavy-duty machines within the Pezzolato line of drum chippers, their drum diameter measures 820 mm.

Able to produce up to 150 m³/h of wood chips, with high yield guaranteed. The feeding mouth and the drum width distinguish the two models.

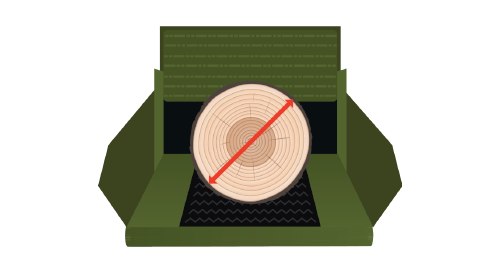

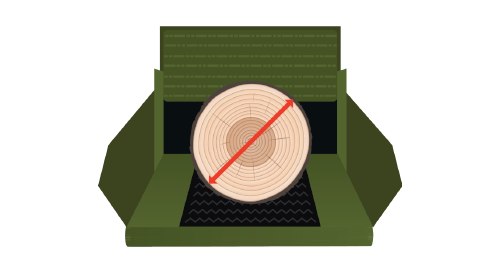

The Pezzolato solid drum, well-known for reliability, wear-resistance and no maintenance, has been designed to guarantee the best quality wood chips, either small or big dimensions. It is staggered section type in order to distribute the machine’s effort equally, reducing vibrations, noise and consumption.

The sharp cut through the blades and the large drum’s inertia reduce the machine’s efforts and stress, thus confirming the well-known solidity of Pezzolato drum chippers.

The wear spare parts of all machines are cost effective and simple to replace in short maintenance times and cheap.

The integrated computer suggests any ordinary and extraordinary maintenace operations to be performed according to the manufacturer’s maintenance plan.

| TECHNICAL DATA | PTH 1000/820 | ||

|---|---|---|---|

| Diesel engine power | hp/kW | VOLVO 405KW - 551 | |

| Diesel engine power | hp/kW | JOHN DEERE 410KW - 550 | |

| Max chipping diameter soft wood | mm/in | 600 mm / 23.62'' | |

| Max chipping diameter hard wood | mm/in | 450 mm / 17.72'' | |

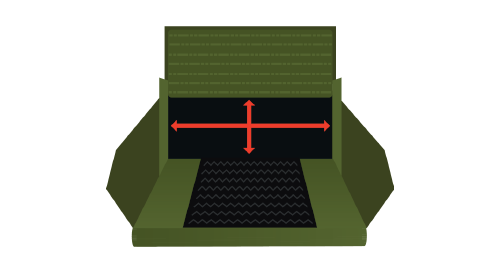

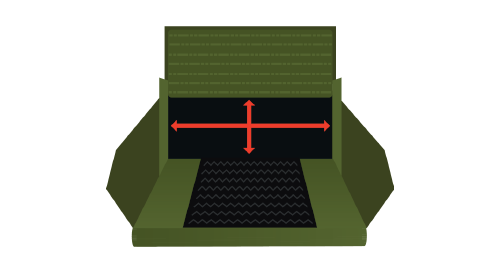

| Maximum inlet passage | mm/in | 1000 x 900 mm / 3' 3.37'' x 35.43'' | |

| Knives | n° | 4 / 8 | |

| Hourly throughoutput | m³/h | until 150 | |

| Drum diameter | mm/in | 820 mm / 32.28'' | |

| Drum width | mm/ft | 1000 mm / 3' 3.37'' | |

| Hooked steel feeding conveyor width | mm/ft | 1000 mm / 3' 3.37'' | |

| Hooked steel feeding conveyor lenght | mm/ft | 2200 mm / 7' 2.61'' | |

| Weight | kg/lbs | 15000 kg / 33069 lbs |

EXTRAS AND CONFIGURATIONS

SIEVING GRIDS

Sieving grids for chip calibration with different sizes, easy to replace

SPECIAL DRUM

Special drum to produce extra size chips: it improves production capacity 15% and reduces fuel consumption 16%

DRIVE-LINE HOPPER

Drive-line hopper, to feed the machine with voluminous material

HYDRAULIC TRACTION

Hydraulic traction, to easily move the machine in impervious paths

C-SHAPED WOOD-SPLITTER

C-shaped wood-splitter with or without chain saw

HYDRAULIC FAN

The chips expulsion fan with continuous speed regulation allows adjusting the speed to the real necessities, decreasing energy need.

LOW-OR HIGH-SPEED TOWING TRAILER

Low or high-speed towing trailer, with air or hydraulic brakes

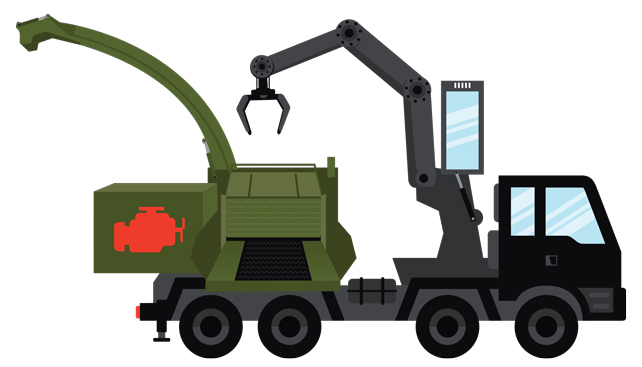

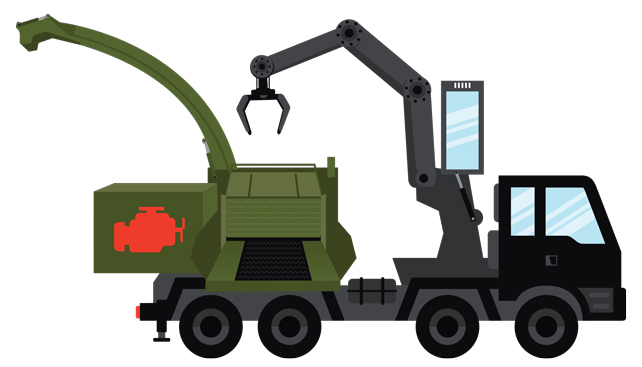

FORESTRY CRANES

Forestry cranes, with or without cabin, in customised configuration

TELESCOPIC LEGS

Telescopic legs enable transportation of the chipping unit on several vehicles

DISCHARGE BELT

Discharge belt, to obtain betterquality chips

ROTATING THRUST BLOCK

Rotating thrust block (fifth wheel), to feed the machine right or left hand

MACHINE SET UP ON A TRUCK WITH 4 AXLES

TRACKS

Tracks to drive the machine in roush terrain

RECOVERING COLLECTING SCREWS

Recovering collecting screws, under the lower feeding roller, to keep the working area clean

LCD COLOR DISPLAY AND EXPECTIVE CAMERAS

LCD color Display and inspection camera

Other extras and configurations

- REVERSIBLE FANS FOR RADIATOR CLEANING

Reversible fans for radiator cleaning, to clean the motor radiator and save fuel

- MOUNT ON FORESTRY MOUNT ON FORESTRY TRAILERS AND FORWARDERS

PTO and Diesel Engine powered chippers are available to mount on Forestry trailers and forwarders.

- INTEGRATED CONTAINER

Integrated container, with hydraulic pivoting, to collect chips where there is difficult access for other vehicles

TECNOLOGIES

INFORMATION REQUEST

Autonomous motor

Autonomous motor Power take off tractor

Power take off tractor

VOLVO 405KW - 551 Hp Diesel engine power

JOHN DEERE 410KW - 550 Hp Diesel engine power

600 mm / 23.62'' Maximum chipping diameter

1000 x 900 mm / 3' 3.37'' x 35.43'' Maximum inlet passage

Autonomous motor

Autonomous motor Power take off tractor

Power take off tractor

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US