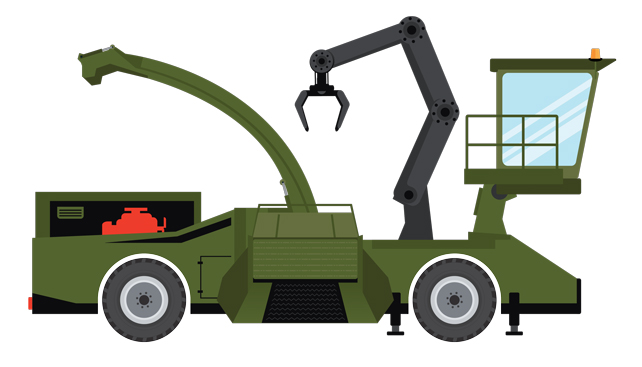

Truck Drum chipper PTH 1400/1000 ALLROAD

Truck Drum chipper PTH 1400/1000 ALLROAD

GREENLINE

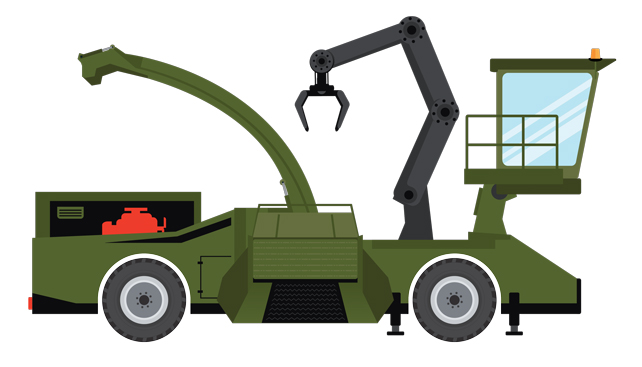

Maximum mobility thanks to the four driving wheels (NOKIAN 650-65 R38), all steering, allowing three steering modes: both axles together, each axle individually or the front axle only.

Two engines are available: with VOLVO PENTA TWD 1683 engine, 6 cylinders, 16 litres, 585 kW, 796 hp, 3650 Nm and with CATERPILLAR C18 engine, 6 cylinders, 18 litres, 563kW, 755 hp, 3504 Nm (which does not require AdBlue).

Crane Palfinger Epsilon S110F104, arm’s length 10,1 m with clamp FG31R and electric controls by means of joysticks. Positioned at the very center of the machine for better distribution of weights for both during transport and the working phase, avoiding abnormal twisting on the vehicle frame.

4 stabilising feet, two with side exit, in order to optimize the machine stability and thus increase the operator’s comfort.

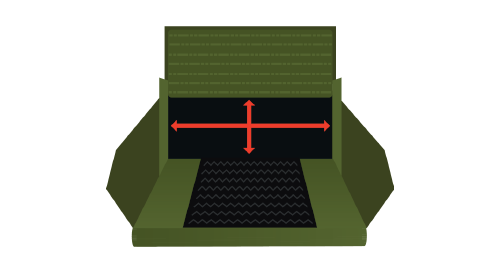

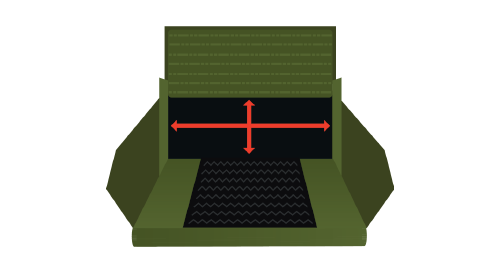

Wide loading hopper especially designed for the processing of voluminous material, equipped with a feeding chain, 1400 wide and positioned at 1050 mm from the ground for faster loading operations, either with little piles or great stacks of wood.

Pezzolato’s closed drum, well known for its reliability and guaranteed to last the machine’s lifetime; designed to guarantee quality chips both small and big size. Drum width 1400 mm with a weight of about 4500 kg: it is staggered drum in order to better distribute the machine stress, decreasing vibrations, noise and fuel consumption.

Comfort cabin, which can be adjusted in height and in all directions to improve the visibility of the loading area and of the unloading conveyor during the use of the crane. Wholly glassed and air-conditioned, it has all controls for total management of the machine either during the machine drivings and during the chipping phase.

Optimized software that assures that the operator can displace the vehicle in the middle of the yard without stopping the chipping; it can pass automatically from the configuration on the road to the working one in less than 60 seconds.

Fan for the expulsion of the chips, hydraulically driven with stepless change of speed so that the rpm can be adjusted according to the real needs, reducing consumption and the production of too fine chips. The speed, adjusted by the operator, is kept constant by the system, even if the r.p.m. of the main engine changes.

Fan’s and unloading conveyor’s wearing parts are composed by wear proof plates including a standard steel base and some carbide units (CDP – Castodur Diamond Plates). The CDP is actually the best solution on the market for wear proofing uses while working with wood.

| TECHNICAL DATA | Truck Drum chipper PTH 1400/1000 ALLROAD | |

|---|---|---|

| Diesel engine power | hp/kW | 796 / 585 VOLVO |

| Diesel engine power | hp/kW | 755 / 563 CAT |

| Maximum chipping diameter | mm | 800 mm / 31.50'' |

| Maximum inlet passage | mm/in | 1400 x 1100 mm / 4' 7.12'' x 3' 7.31'' |

| Knives | n° | 6 |

| Hourly throughoutput | m³/h | until 380 |

| Drum diameter | mm/ft | 1000 mm / 3' 3.37'' |

| Drum width | mm/ft | 1400 mm / 4' 7.12'' |

| Hooked steel feeding conveyor lenght | mm/ft | 2000 mm / 6' 6.74'' |

| Hopper width | mm/ft | 2100 mm / 6' 10.68'' |

| Hopper height from the ground | mm/ft | 1050 mm / 3' 5.34'' |

| Weight | kg/lbs | 32000 kg / 70548 lbs |

EXTRAS AND CONFIGURATIONS

INFORMATION REQUEST

Volvo 796 HP engine

Volvo 796 HP engine

380 m3/h Production capacity

1400 x 1100 mm / 4' 7.12'' x 3' 7.31'' Maximum inlet passage

Volvo 796 HP engine

Volvo 796 HP engine

DO YOU NOT KNOW WHICH MODEL IS SUITABLE FOR YOUR NEEDS?

REQUEST A COMMERCIAL SUPPORT TO IDENTIFY THE MOST SUITABLE MACHINE FOR YOUR NEEDS

CONTACT US